|

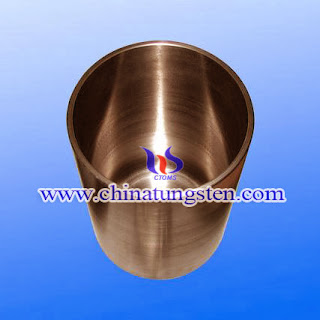

| tungsten crucible |

Melting point of tungsten high boiling point, high temperature strength, wear resistance, corrosion, thermal conductivity, thermal expansion coefficient, good hardenability. Tungsten crucible smelting of rare earth is widely used, quartz glass, electronic spraying, crystal growth,etc.

Tungsten melting point, boiling point, high temperature strength, anti-friction, corrosion resistance, thermal conductivity, thermal expansion coefficient, good hardenability, thanks to such excellent properties, tungsten is widely used in rare earth smelting crucible, quartz glass, e-coat , crystal growth and other industries.

Production Process: Molybdenum Powder-Sifted-Combined Batch-Isostatic Pressing-Rough Blanks Lathe-IF Sintering-Boutique Vehicle Processing-Packaging

Product Details I. Physical and chemical properties:

1.Purity: W ≥ 99.95%;

2.Density:≥ 19.25g/cm3;

3.The Maximum Application Temperatures: 2400 ℃.

No comments:

Post a Comment