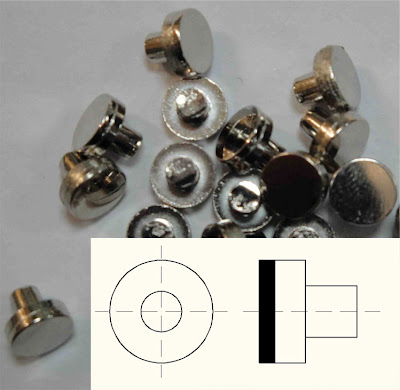

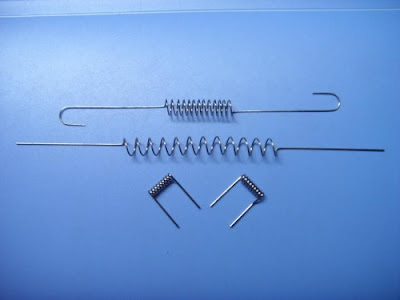

Tungsten pin

Tungsten pin is pin made of the material—tungsten. Since it is made of tungsten, tungsten pin owns the properties of high melting point, high corrosion resistance, tensile strength and low coefficient of thermal expansion. When added steel or other element, its hardability would be improved.

The surface condition of tungsten pin is smooth and bright. Moreover, no stain, dirt, oxides, drawing tracks, scratches and damages are admitted on the surface of tungsten pin.