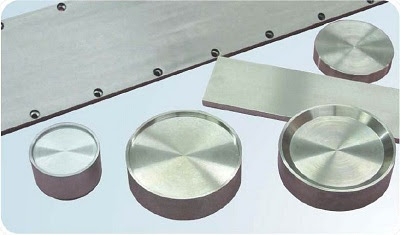

Molybdenum Alloy

Molybdenum alloy has excellent strength and mechanical stability at high temperatures (up

to 1900°C). Their high ductility and toughness provide a greater tolerance for

imperfections and brittle fracture than ceramics.

The

unique properties of molybdenum alloy are utilized in many applications:

High

temperature heating elements, radiation shields, extrusions, forging dies, etc;

Rotating

X-ray anodes used in clinical diagnostics;

Glass

melting furnace electrodes and components that are resistant to molten glass;

Heat

sinks with thermal expansivity matching silicon for semiconductor chip mounts;

Sputtered

layers, only Ångstroms (10-7 mm) thick, for gates and interconnects on integrated

circuit chips;

Sprayed coatings on

automotive piston rings and machine components to reduce friction and improve

wear.