Products made of

tungsten and molybdenum are the main material for sapphire growth furnace. The products of

tungsten and molybdenum are made of the material of

tungsten and molybdenum whose purity are over 99.95%. They include tungsten crucible, tungsten plate, tungsten sheet, tungsten wire, tungsten electrode screen and molybdenum crucible, molybdenum plate, molybdneum sheet, molybdenum heater, molybdenum holder and molybdenum electrode screen. Besides the pure tungsten and molybdenum products, tungsten rhenium wire is also a main product for the application of

sapphire growth furnace.

The color of

tungsten and molybdenum for

sapphire growth furnace are grey. Tungsten is widly used as parts of

sapphire growth furnace for its unique properties, such as high density, small volume, excellent hardness, superior wearing resistance, high ultimate tensile strength, high ductility, high temperature resistance, high radiation adsorption capability, etc. Molybdenum products also have similar properties, such as high denshity and high melting point.

Sapphire growth furnace is a production proven system that produces high quality boules of exceptional crystal for the industry of LED. This furnace has been a increasing demand system for the high volume sapphire producers. One of the main reason is the fast increasing requirement of LED. In the system of

sapphire growth furnace,

tungsten and molybdenum products are the most choice for the sapphire growth, or crystal growth.

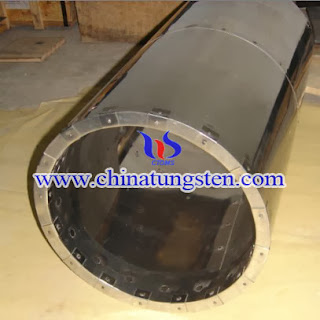

Tungsten and molybdenum for

sapphire growth furnace composed lots of parts. Tungsten products for

sapphire growth furnace includes tungsten crucible, tungsten crucible cover, tungsten bracket, tungsten heat shield, tungsten electrode screen, tungsten heater, tungsten wire heater and tungsten rhenium. As for molybdenum products for

sapphire growth furnace, they consists of molybdenum cover, molybdenum barrel screen, molybdenum crucible, molybdenum boat, molybdenum heat shield, molybdenum bracket, molybdenum thermal field, molybdenum heating furnace, molybdenum hook, molybdenum mandrel, molybdenum stream mouth and molybdenum seed chunk. These mentioned products are parts of sapphire growth furnace. There are some other designed

tungsten and molybdenum for

sapphire growth furnace provided by Chinatungsten Online.

Tungsten crucible and molybdenum crucible are main products for sapphire growth. Tungsten and molybdenum crucible are used as heating element in the process of sapphire crystal growth. For the property of high melting point of tungsten crucible and molybdenum crucible, tungsten and molybdenum are better choice for the sapphire growth for they will not melt with the crystal and can assure the prurity and high quality of the crystal, which can be produced high qualtiy LED material.

The best manufacturing technique of

tungsten and molybdneum products are sintering ones for they own the property of high quality and reasonable price.

The sapphire is one of the three gem-varieties of corundum, the other two being ruby -- defined as corundum in a shade of red—and padparadscha—a pinkish orange variety. Although blue is their most well-known color, sapphires may also be colorless, and are found in many colors including shades of gray and black.

|

molybdenum crucible

|

The cost of natural sapphires varies depending on their color, clarity, size, cut, and overall quality – as well as their geographic origin. Significant sapphire deposits are found in Eastern Australia, Thailand, Sri Lanka, Madagascar, East Africa, and in North America in a few locations, mostly in Montana.Sapphire and rubies are often found together in the same area, but one gem is usually more abundant. Color in gemstones breaks down into three components: hue, saturation, and tone. Hue is most commonly understood as the "color" of the gemstone. Saturation refers to the vividness or brightness or "colorfulness" of the color, and tone is the lightness to darkness of the color. Blue sapphire exists in various mixtures of its primary (blue) and secondary hues, various tonal levels (shades) and at various levels of saturation (vividness).

Using tungsten and molybdenum products to produce sapphire is called prefabricated mehod, and this method can also produce high qualtiy sapphire, but also cost effecticve.

If there is any other question refer to

tungsten and molybdenum for

sapphire growth furnace, please feel free to contact us through the following methods.

Email:

sales@chinatungsten.com

Tel.: +86 592 512 9696/ +86 5925129595

Fax: +86 5925129797