|

| infrared transparent window materials |

1)Mechanical strength : infrared transparent window material should have sufficient strength to withstand the high speed movement of the pressure load ;

2)Thermal stability: the infrared transparent window material should be subjected to high aerodynamic heating and thermal shock caused by the change , the transmittance and the refractive index changes with temperature should be a significant change occurs;

3)Chemical stability: infrared transparent window material is exposed to the air, the air should be able to prevent the salt solution or etching gas corrosion , and difficult to deliquescence ;

4)High optical transmittance , must be able to efficiently transmit the ultraviolet to the infrared radiation ;

5)Good optical properties, optical scattering of small and good uniformity index;

6)To meet the requirements of large-size window.

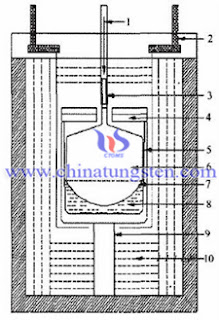

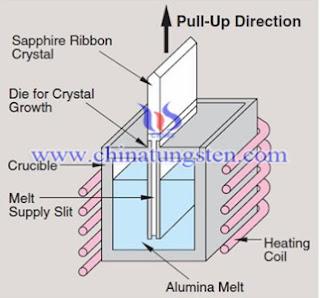

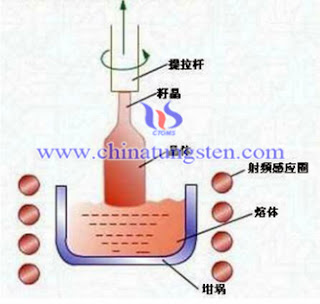

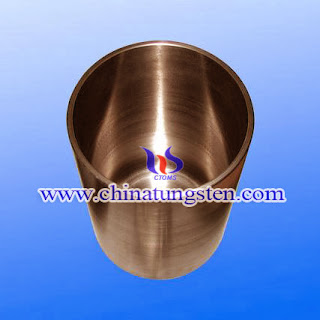

Although today there are hundreds of species of certain bands of infrared radiation through optical materials , but can have both optical properties and can withstand harsh environments infrared transparent window material , but very few . Commonly used infrared transparent window has zinc sulfide (ZnS), zinc selenide(ZnSe), gallium arsenide (GeAs), sapphire (Sapphire), spinel (Spinel), alumina, aluminum nitride (ALON), yttrium oxide,(Yttria), magnesium oxide (MgO), diamond , magnesium fluoride (MgF2) and so on .Zinc sulfide, zinc selenide , gallium arsenide in the 8-12μm.Band has good permeability,but the high temperature chemical decomposition occurs lost performance. Diamond has excellent mechanical strength , optical properties and thermal conductivity , but also at 650 ℃ no longer applicable , for this would lead to oxidation and graphitization . Many oxides can not be used because severe thermal shock and stress can cause the material oxide atoms multi-photon absorption.It can be used to make high speed missile fairing only yttrium oxide material,spinel, aluminum nitride, alumina, sapphire and so on. Sapphire Single crystal as an excellent wave-transparent materials in the ultraviolet,visible,infrared,microwave waves have good penetration rate , to meet the multi-mode combined guidance(TV,infrared imaging,radar,etc.)requirements;also has a sapphire crystal excellent mechanical properties,chemical stability, high temperature resistance , high strength , hardness, can meet hypersonic missile wave-transparent materials for the demanding requirements.Preparation of the material aspects of sapphire single crystal can be grown,and then molding , product performance and performance of the same single crystal and other materials using mainly hot casting powder sintering , and its performance to be slightly lower than the original.Therefore, sapphire has become advanced national high-speed fighter aircraft, missiles and other medium-wave infrared transparent window material an excellent choice . United States, Britain,Russia,Israel and other military powers are struggling to carry out large-size sapphire infrared window studies,and has been implemented.Now ¢ 300-500mm ¢ 120mm sapphire crystal or sapphire hemispherical dome above preparation capabilities , used in the United States series Aim-9X Sidewinder air to air missiles , the South African A-Darter air missiles, the Israeli Python-4 air to air missiles, advanced English Asraam close air to air missiles. Sapphire window with excellent performance as a wide-band optical materials optoelectronic devices for military applications, the time is not very long. In the 1960s, the U.S. military has this despite the research, but the real sapphire window for a larger range of applications and development in the 1980s , which is computer-controlled optical processing machine development are closely related . Recently, in some reports , we can see some very specific applications .For example in 2001 , the U.S. Army has ordered the direction of Exotic photoelectric Branch 88 sapphire window , equipped with F-16 fighter airborne navigation pod FLIR target . 2000 Thales UK signed a $ 33 million photoelectron photoelectric mast contract to produce six CM010 Optronic Mast.CM010 photoelectric mast all with sapphire crystal viewing window . U.S. new generation fighter.F-35 Joint Strike Fighter optical tracking system (Electro-Optical Targeting System, EOTS) window consists of seven sapphire wafer surface coating composition , which provides 360-degree omni-directional vision. Figure 6 shows the F-16, F-35 fighter jets and optical tracking system sapphire windows.

Over the next 200 years , people were Infrared Physics , infrared optical materials, infrared optical systems, infrared detector , infrared spectroscopy and related applications for exploration and research , in which the background research for military purposes is undoubtedly bear the brunt. For example, the mid- 1950s , the infrared -guided air- point sources - air missile was born , this is the famous American "Sidewinder" missiles;1960s developed airborne infrared scanners, looking infrared equipment and the early space infrared instruments ; 1970s emerged common components infrared camera , infrared warning systems and spaceborne infrared instrument more space ; 1980s development of FPA -based infrared infrared military equipment and space reconnaissance,early warning technology . Recently, the infrared technology has been successfully used not only in the field of full play to its advantages , will be more effectively applied to the rapid development of optoelectronic countermeasures,optical communications and directed energy weapons . In the future new combat forms and characteristics,the various fighters, missiles are increasingly high speed, in order to improve their offensive and penetration ability . The fourth -generation fighter aircraft can cruise at supersonic speed , next-generation air - air combat missiles , cruise speeds of up to 3 ~ 5Ma. Meanwhile, in severe electrical interference conditions, in order to improve the sensitivity and anti-jamming capability missiles , guided way gradually to a variety of guided modes composite ( TV , infrared imaging , radar , etc.)development.Therefore, in order to achieve future fighter aircraft, missiles, high-speed,multi-mode combined guidance , and its infrared detectors infrared transparent window material properties should meet the following basic requirements.