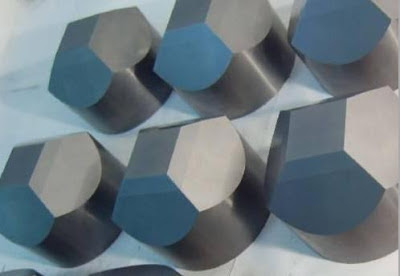

Cemented

Carbide Brazed Tips

Cemented carbide brazed tips are with high hardness,

which can keep cutting capability when working under high temperature. It

always has a thin metal blade or disk with a sharp, usually toothed edge, which

can be used for cutting wood, metal or other hard material. Cemented carbide

brazed tips are also used in surface processing of cast irons, colored metal

and alloys, as well as nonmetal materials.