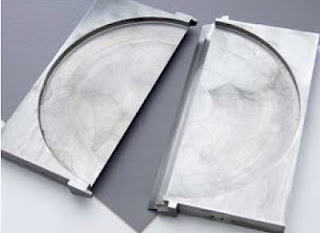

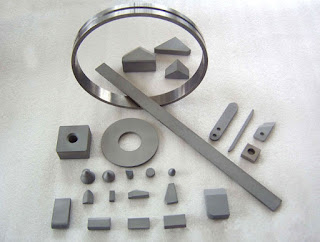

Tungsten Alloy Housing Shielding

With rapid development of medical science, more and more radiation instruments are used in our lives. Medical instruments and nuclear power stations have become widespread and are now affecting all our lives. It is essential that people paid more attention to radiation and even more important for the institutions to protect public from the radiation exposure and to make sure to protect every radiation source of X-ray radiation, gamma radiation (energetic electromagnetic radiation), radiation of alpha particles (helium atoms) beta particles (electrons) and cosmic radiation, etc.

In order to protect patients and personnel from harmful effects of ionizing radiation, such as breast cancer, skin cancer, etc an excellent radiation-absorbing medium is badly needed. Tungsten alloy housing shielding is the material to be used for radiation shielding.

Tungsten alloy is ideal for tungsten alloy radiation shielding against X-rays and gamma radiation. The very high density of tungsten alloy housing shielding (more than 60% denser than lead) allows a reduction in the physical size of shielding components, without compromising their rigidity or the effectiveness of the tungsten alloy radiation shielding characteristics.