Tungsten Alloy Environment

Tungsten is a metal with many industrial and military applications, including manufacturing of commercial and military ammunition. Despite its widespread use, the potential environmental effects of tungsten are essentially unknown. Tungsten alloy environment is a hot topic for environment protection. This study addresses environmental effects of particulate and soluble forms of tungsten, and to a minor extent certain tungsten alloy components, present in some munitions formulations. Dissolution of tungsten powder significantly acidifies soils. Tungsten powder mixed with soils at rates higher than 1% on a mass basis, trigger changes in soil microbial communities resulting in the death of a substantial portion of the bacterial component and an increase of the fungal biomass. It also induces the death of red worms and plants. These effects appear to be related with the soil acidification occurring during tungsten dissolution. Dissolved tungsten species significantly decrease microbial yields by as much as 38% for a tungsten media concentration of 89 mg l-1. Soluble tungsten concentrations as low as 10-5 mg l-1, cause a decrease in biomass production by 8% which is possibly related to production of stress proteins. Plants and worms take up tungsten ions from soil in significant amounts while an enrichment of tungsten in the plant photosphere is observed. These results provide an indication that tungsten compounds may be introduced into the food chain and suggest the possibility of development of photo remediation-based technologies for the cleanup of tungsten contaminated sites.

Very little tungsten has been detected in the dew soils that have been analyzed for it, although around an ore-procession plant in Russia levels as high as 2000 ppm was found. The concentration of the element in natural waters is very low.

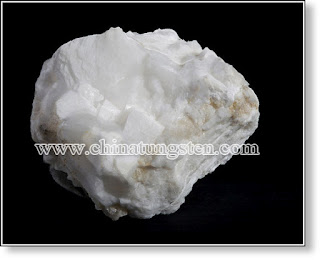

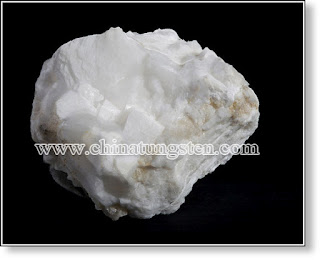

There are several minerals of tungsten; the most important are sheltie and wolfram. The main mining area is China, which today accounts for more than two-thirds of the world's supply. Other places with active tungsten mines are Russia, Austria, Bolivia, Peru and Portugal. World production is around 40.000 tons per year and reserves are estimated to be around 5 million tones. Tungsten is also recycled and it meets 30% of demand.

Effects of tungsten on the Environment

Tungsten metal powder administered to animals has been shown in several studies as not altogether inert. One study found that guinea pigs treated orally or intravenously with tungsten suffered from anorexia, colic, in coordination of movement, trembling, dispend and weight loss. This product is not expected to be hazardous for the environment. No specific ecotoxicity data is available for this product. Tungsten alloy environment friendly is more and more popular of public.

For many years, lead and depleted uranium were commonly used as a functional, cost-effective, and reliable choice in the manufacturing of munitions. When first brought into use, scientists knew little about the environmental effects of these materials. Depleted uranium was typically seen as constituent of kinetic energy penetrators (which uses kinetic energy to penetrate the target) in medium to large caliber munitions. Lead, most frequently used in small arms ammunition, was at that time also found in a variety of household products such as gasoline, rubber, paint, and printing supplies.

It was only after decades of use that scientists revealed that these materials pose serious threats to the environment. The search was on for a "green" alternative in munitions components.

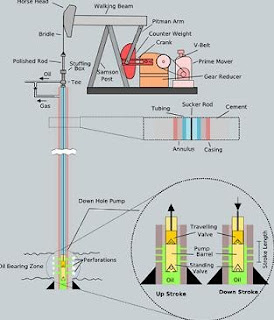

Extensive analysis resulted in the testing of tungsten (W), a naturally occurring element that exists in the form of minerals and other compounds, as a replacement for lead in small arms ammunition. Tungsten was considered to be environmentally benign, relatively insoluble in water, and nontoxic. Furthermore, tungsten-based munitions performed the same and were similar in costs to lead alternatives.

It seemed to be the ideal solution for greener munitions. Through the Department of Defense's (DoD) Green Ammunition Program, the lead core in military bullets was replaced with tungsten composites. The DoD hoped to save millions in remediating contamination while at the same time contributing towards advancements in green technology.

However, after years of tungsten use, the DoD chose to re-evaluate the material's potential environmental impact. Researchers from Stevens Institute of Technology identified a growing concern that tungsten was not as "green" as initially thought, and began investigating how a cooperative pursuit of improved environmental protection and DoD requirements may be beneficial.

In response to this concern, Professors Christos Christodoulatos and Washington Braida of the center for environmental systems have undertaken a massive research effort aimed at identifying the specific nature of tungsten-based munitions and ultimately at minimizing the life-cycle environmental impacts and cost of munitions by researching the DoD's triple bottom line: mission, environment, and community.