Sapphire Furnace tungsten products are steel gray to tin white hard metal, very pure tungsten can see-saw sawing (pure tungsten is very brittle and difficult to process). Tungsten processing means are forging, tensile and impact. In all the highest melting point of tungsten metal for 3415 ℃, the lowest vapor pressure at the highest tensile strength (1650 ℃ when). Corrosion performance is very good, most of the erosion of its small inorganic acids. In the air to form a protective surface oxide, but will be completely oxidized at high temperature. Molybdenum product is high temperature, high melting point refractory metal.

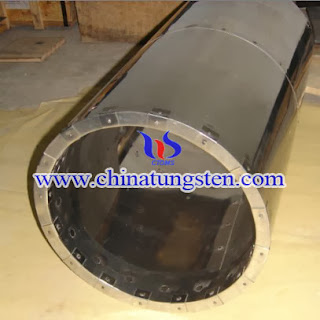

Sapphire growth furnace designed to nurture through Kyropoulos sapphire single crystal . This method is the tungsten crucible by the raw materials ( alumina ) was heated to its melting point of 2050 ° C or more, and then gradually reduce the melting temperature and allowed to crystallize into a specific granules . The growing furnace in a heat-insulating casing with a special lid closed and the heater constructed in crystallizer . Therefore appeared Sapphire tungsten and molybdenum products Dan Changjing furnace .

Crystal growth furnace is an important carrier of tungsten and molybdenum crucible . Using iridium crucible generally iridium crucible itself is the heat generator , but using tungsten, molybdenum crucible is less used crucible itself do heat . Ikal-200 type crystal growth furnace , tungsten crucible , molybdenum crucible , molybdenum heat shield , tungsten heating body , volatilized at high temperatures molybdenum and tungsten atoms. Of course, tungsten , molybdenum crucible itself is not doing no heating element , is relative , process selection and temperature field settings are very critical factor . Different crystal growth method using the crucible will be different, such as the Kyropoulos (KY) Average of tungsten crucible , heat exchange method (HEM) generally used molybdenum crucible , because the heat exchange last to fall through to take a single crystal , and the molybdenum crucible cheapest price . According crucible manufacturing process, can be divided into pressed and sintered crucible and the crucible spinning , pressed and sintered crucible of lower quality , purity, low density , relatively short life , the price is relatively cheap ; spinning crucible of higher quality, purity , density higher , longer service life , high price. Domestic crystal growth furnace is generally used to suppress sintering crucible .

tungsten and molybdenum for sapphire growth furnace |

Tungsten and molybdenum products are suitable Sapphire Dan Changjing key carrier. Using tungsten and molybdenum as a material , can effectively protect the purity sapphire as tungsten and molybdenum are high temperature refractory metal , not react with sapphires .

No comments:

Post a Comment