|

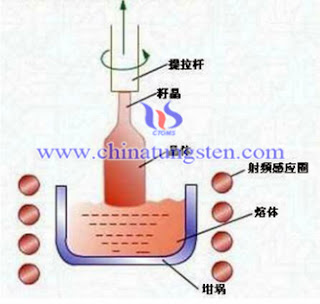

| Czochralski crystal pulling |

Referred to CZ method.Pulled from the melt Czochralski crystal growth method

First in 1918 , and since 1964 Poladino Rotter first applied to the sapphire crystal growth , the successful growth of high quality sapphire crystal , crystal growth schematic diagram shown in Figure 11 . After the first material is heated to melting temperature difference between the melting point to form a cold. Thus molten metal solidification begins on the seed surface and the same crystal growth and crystal structure of a single crystal seed . Seed simultaneously pulled up very slowly , and is accompanied by a certain rotational speed , with the seed crystal pulled up , gradually solidified molten metal at the liquid-solid interface seed , and thus the formation of a single axisymmetric Jingjing stick. Pulled up in the process, pulled by controlling the pace of deployment , were grown crystal neck (Neck), Crystal Crown (Shoulder), crystal body (Body) and crystal tail. Each part has its own purpose , crystal growth is mainly used to eliminate cervical dislocation . Because the crystal growth process is complex, difficult to control the amount of dislocations generated , so most of the crystal growth process , both to eliminate dislocations as the main choice. End grain long neck , to be slow lifting speed , the crystal diameter is increased to the desired size , this step is the crown crystal growth . When the crystal diameter is increased to the desired size , with regard to the speed constant thrust , this part of the crystal diameter is fixed, which is part of the crystal body . This section is to be used as part of the substrate material for industrial use , so the growth , the need to be careful . When the crystal length when finished , it is necessary to leave the molten ingot , then pulled up the speed increases , the grain diameter of the rod out, until it becomes point-like , and then be separated from the molten metal . End of this crystal growth step , which is intended to prevent molten crystal rod and rapid separation , the resulting thermal stress , if the thermal stress generated in the separation , this thermal stress will produce crystal rods and slip dislocation lines defects. In the current semiconductor industry,CZ method is the most commonly seen in the crystal growth method , since a larger diameter can grow the crystal, so about 85 % of the semiconductor industry are used

CZ method to grow a single crystal rod . Main features of the method :

1)The crystal growth process,can facilitate the observation of crystal growth;

2)The free surface crystal growth , the crucible is not mandatory effect, can reduce the stress of the crystal ;

3)You can easily use the seed desired orientation and the " necking " process, helps to relatively fast growth rate higher quality crystals with good integrity;

4)Crystals,the crucible and the forced convection caused by the rotation of gravity caused by natural convection interactions , the complex role can not overcome the flow , easy to produce crystal defects;

5)Mechanical perturbations in the growth of large diameter crystal is easy to make the crystal defects .

No comments:

Post a Comment