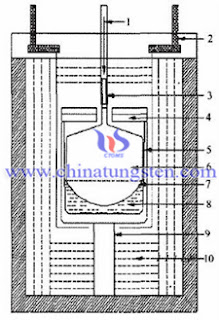

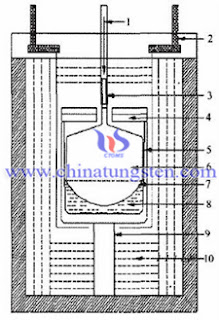

Cold Heart put the shoulder trace Czochralski (

SAPMAC) also known as micro- pulling rotation Kyropoulos is Harbin University Institute of composite Materials and Structures on Kyropoulos and improved Czochralski method evolved on the basis for the growth of large-size sapphire crystal method , mainly in Ukraine Donets produced Ikal-220 -type crystal growth furnace based on the improvement and development. Crystal growth system mainly comprises a control system, vacuum system , heating element , cooling systems and thermal protection systems. The figure is a cold heart to put the shoulder trace Czochralski system diagram , SAPMAC single crystal growth method , the outlook is usually pear-shaped , crystal diameter can grow into a crucible diameter smaller than 10 ~ 30mm size. The seed crystal is processed into a split form , the use of seed crystals of the heat exchanger at the bottom clamp . Heat fixing the seed crystal to be completed , the crystal rotation and pulling , and the heat exchanger , between the crystal and the melt heat exchange effect. Heater , cooling systems and thermal protection system synergy for crystal growth to provide a uniform , stable and controllable temperature field . According to which the seeded crystal growth , put the shoulder , Equal and annealing and the cooling phase is characterized by adjusting the temperature of the working fluid in the heat exchanger , flow rate , heating temperature (heating body can provide the crucible wall temperature ) can precise control of the crystal / melt temperature gradient , the heat transfer to complete crystal growth . Cold Heart put the shoulder trace sapphire crystal grown by Czochralski method , usually the entire control of the crystal growth process is divided into four stages, namely seeding , put the shoulder , Equal , annealing and cooling stage . Seeding stage and put the shoulder is the use of adjusting heat exchanger cooling capacity , the appropriate heating temperature with a certain reduction ( heating system can provide the crucible wall temperature ) way to achieve the crystal necking and put the shoulder control . At this time the crystal growth rate and the temperature gradient projection screen is large, which is conducive to the use of larger discharge shoulder angle , reducing the distance put the shoulder , preventing the interface flip while being able to dislocations within the seed crystal defects such as the original fast from crystals spread to the crystal surface , effectively reducing the content of the crystal defects . A large temperature gradient interface can also improve the driving force of crystal growth , to increase the interface stability. Subject to the crystal diameter grows to the desired size ( cold heart put the shoulder trace Czochralski crystal diameter can grow to distance crucible 1 ~ 3cm) , the crystals begin to equal diameter growth path into the other phase. As the crystal size grew up , the heat exchanger efficiency decreases rapidly to the crystal growth , the crystal growth phase into the other path , mainly by reducing the heating temperature ( heating system can provide a crucible wall temperature ) to achieve crystals growth .

Main Features of The Method :

1)Put the shoulder by a cold heart , ensuring the large size of crystal growth , the entire end product to the genetic characteristics of the process of crystallization good material quality.

2)High-precision micro- pulling with energy control , so that the crystal growth process without significant thermal disturbance probability of defect initiation significantly lower than other methods .

3)Since only trace Thira , reducing the temperature field perturbations. Make more uniform temperature field , thus ensuring crystal Health

Long success rate.

4)In the crystal growth process , the crystal is not made crucible , is still in the hot zone. Can be precisely controlled

The cooling system of its speed and reduce the thermal stress.

5)Suitable for the growth of large-size crystal material is Kyropoulos comprehensive utilization of more than 1.2 times .

6)Use water as the working fluid within the heat exchanger , the crystal can be achieved in-situ annealing , the test cycle shorter than other methods , the cost is low.

7)In the crystal growth process , can facilitate the observation of crystal growth ;

|

| cold heart out the shoulder micro system diagram czochralski method |

8)The crystal growth of the free liquid surface , the crucible is not mandatory effect, can reduce the stress of the crystal ;

9)It can easily use the desired orientation seed crystal and the " necking " process, helps to relatively fast rate.

Cold Heart Put The Shoulder Micro System Diagram Czochralski Method

1.Cooling Water Rod;2.Heater;3.Seed Holder;4.Level Thermal Diffusion;5.Crucible;6.Crystal;7.S/L interfaces;8.Melt;9.Bracket;10.Radiating

No comments:

Post a Comment